An emerging trend in automotive electrical infrastructure is the development and implementation of 48-volt systems. This article deals with the history of the system’s development and the rationale for this new architecture. There is a companion article entitled 48-Volt Systems and Connectors: QA with an Expert in a separate article in this issue. In that article, we interview Boris Ketscher, Product Manager at TE Connectivity. Boris dives deeper into 48V technology and touches on salient points for our industry. He also discusses TE’s development of connectors for 48V systems.

48 Volt System

Since the 1950’s, 12V electrical systems have been the norm for the automotive industry. If you venture to classic car shows, you may encounter the old 6V electrical systems common in pre-1955 automobiles. Those systems were adequate to crank a six-cylinder engine, and maybe power an AM radio. But as manufacturers produced bigger, higher compression engines, and options like power seats, power windows, etc., more power was needed. For the past 70 years, the 12V system has proved adequate in starting the engine, charging the system (alternator), and operating the ever-increasing load of electronic devices.

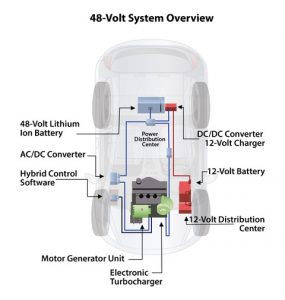

Modern cars now consume much more electrical energy than they used to. Features like advanced climate control, driver assistance computers, and complex infotainment systems are outpacing the capacity of the 12V system. Enter the 48V system. The 48V system minimizes resistive loss of energy and allows higher currents and greater power delivery so these systems can be more effective and work quicker. Figure 1 shows a basic schematic of how the system works.

But the biggest advantage of the 48V systems is its ability to act as a mild hybrid, thus reducing CO2 emissions. A full hybrid vehicle can travel short distances at slow speeds, solely on electric power. By contrast, the mild hybrid never acts as an electric vehicle. The traditional starter motor and alternator is replaced by an integrated 48V motor generator unit (MGU). The MGU does two things. When the vehicle is coasting or braking, the engine is shut off and it harvests energy back into the battery. The stored energy in the MGU also provides additional torque during acceleration.

Another way the 48V system helps fill the gaps in the internal combine engine power curve is with an e-charger to replace the turbocharger. Because the traditional turbocharger uses exhaust gases to drive the turbo, there is always some lag in pickup. The 48V system powers an electric blower motor in the e-charger to overcome this lag at low RPMs. The combination of these two systems allows for a smooth power curve and allows for the use of smaller more fuel efficient engines.

The industry has too much invested in 12V components to toss this system into the trash bin of history. So, for now, these systems will act in conjunction with each other, with the 48V system handling the more power-hungry components, and our old friend, the 12V system, powering legacy accessories while the engine is not running.

It is predicted that by 2025, one-fifth of all cars sold globally will have a 48V system. The good news for our industry is the necessity for more wiring systems.