There are many factors to consider when deciding on a metal joining method including its tangible and intangible features. Depending on the application, the investment will vary based on joining design, materials to be welded, geometrical shapes, dimensions and sizes, environmental effects, and the mechanical and electrical integrity that the given product demands. It’s not possible to address all joining applications within a single article, so we’ll highlight the automotive wiring harness industry and products to clarify the differences in crimping, soldering, ultrasonic, laser, and resistance welding.

In some cases, ultrasonic welding is the only solution or may not be feasible at all. However, no matter how many variables are being considered in the selection of the joining method, ultrasonic welding seems to offer a better long-term return on investment than all other viable processes.

The initial investment in ultrasonic metal welding equipment is higher relative to other welding processes such as resistance welding and crimping, and mechanical joining, and yet lower than laser welding equipment. So, why has this technology dominated wire harness manufacturing and become a necessity for EV, HEV batteries, and electrical distribution? Ultrasonic welding of non-ferrous metals has been a proven technology for decades. However, since the early 1980s, ultrasonic metal welding has dominated the automotive industry, with automotive wire harness manufacturers as the single largest user of this technology (Figure 1). Due to its efficiency and unbeatable quality, ultrasonic welding replaced mechanical crimping and resistance welding for all car brands almost immediately upon inception. The utilization of ultrasonic welding for automotive wire harnesses has seen even more rapid growth in the last decade due to the increase in electrically powered vehicles (EVs). Telsonic’s innovative and industry-changing torsional welding technique has in large part contributed to this rapid growth due to its unrivaled ability to address challenges such as weld size, welding in smaller areas, geometrical shapes, reaching the weld area, the orientation of welding, and vibration effects on peripheral components.

|

|

|

|

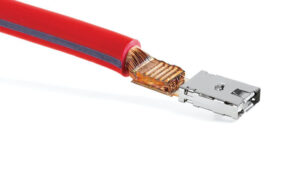

Figure 1 – Conventional ultrasonic welding applications for automotive wire harnesses

An average automotive wire harness contains 180 splices, and that number grows with each vehicle model year. OEMs are adding more electronic features to cars which require more splices. The splices and wire terminations together make up a long and complex heavy harness that controls the entire electrical system throughout the vehicle. Wire splicing has always been a major focus in the manufacturing of wire harnesses due to the inherent labor intensity in wire processing. The industry still applies crimping or resistance welding for applications such as small wire crimping or tin wire splicing. In general, ultrasonic welding is not feasible for tin-plated parts or hard materials such as steel. This is where resistance or laser welding options become viable. Ultrasonic welding is the ultimate option when welding aluminum to another non-ferrous metal. Because of its cold fusion welding nature, aluminum is welded strongly without melting or being significantly affected by heat. The advantages of ultrasonic welding apply to thermally conductive materials, such as aluminum, copper, and magnesium, which can be troublesome to weld by resistance welders and lasers. Ultrasonics is also very useful for joining a thin material with a thick material. If minimal disturbance of material properties due to heat is a requirement, ultrasonics is often the best welding process.

Wire splicing is an excellent example to evaluate some of the joining processes in today’s manufacturing of wiring harnesses. Manufacturers utilized the crimping process for many years before welding became a viable option. Some OEMs just used the clip to crimp the wires in a splice. Some added dipping in a solder bath to secure the electrical integrity. That had the disadvantages of added material (many different sizes of clips), space needed for dedicated presses, the requirement of soldering skills, and impact on wire strands due to the mechanical stress and the heat from the clip and solder. Therefore, welding of wires became very desirable, starting with resistance welding and then the inception of ultrasonic welding. The cold fusion nature of ultrasonic metal welding, its ability to eliminate oxidation before welding, joining of dissimilar metal, very low energy consumption, and ability to weld a variety of splice sizes with one machine and the same universal tooling, were convincing factors in making ultrasonic wire splicing an acceptable process globally. It took several years for wiring harness manufacturers to become familiar with the process and to adopt the technology. Some moved from crimping to ultrasonic welding, and some used resistance welding before moving to ultrasonic welding. Ultrasonic welding equipment offered advantages over other joining methods that are still true today.

Throughout the progression of welding technology over the past 30 years, quality and reliability were always the ultimate deciding factors. The return on investment was easily justified – ultrasonically welded joints presented longer life in vehicles. Today, most of the features in the comparison table below (Table 1) are applicable to other metal welding applications such as wires to terminals, terminals to terminals, and busbars.

Table 1 shows each process’s advantages and direct and indirect costs of operation. There are many cases where one joining method may be clearly the better choice or even the only option. Consider the features in the table below when deciding among multiple joining options.

| Features | Ultrasound | Resistance | Crimping | Soldering | Laser |

| Cold welding process | yes | no | no | no | no |

| Consumables needed | no | no | yes | yes | no |

| Joining dissimilar materials | yes | limited | yes | limited | limited |

| Durability of the connection | excellent | good | moderate | low | good |

| Mechanical strength | high | high | moderate | low | moderate |

| Electrical conductivity | excellent | good | moderate | low | good |

| Change of material property | unchanged | changed | unchanged | changed | changed |

| Power consumption | low | high | low | moderate | moderate |

| Process time | short | short | short | long | short |

| Heat generation | low | high | low | high | high |

| Influence of surface conditions | moderate | moderate | yes | yes | yes |

| Quality control, consistency | high | low | moderate | very low | moderate |

| Occupational safety (vapors, electric shock) | good | low | good | low | good |

| Tool life | high | low | high | moderate | high |

| Qualified operator required | no | no | no | yes | yes |

| Simple automation | limited | limited | good | no | limited |

| Maintenance requirements | low | high | low | low | high |

Table 1- Table of comparisons

The operation/maintenance cost per joint must be validated concurrently but with quality as the highest priority. Here are some of the factors that are considered in selecting a joining method:

- Initial investment and volume

- Output rate

- Consumables

- Electrical consumption – ultrasonic welding requires 5% of that of resistance welding

- Additional infrastructure such as water cooling, ventilation, and additional power installation

- Floor space required for equipment

- Changeover time

- Setup time for each application

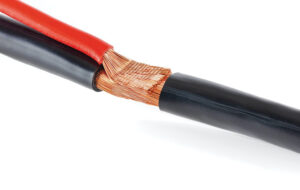

- Tooling life and its effect on quality (Figure 2)

Figure 2 – Tooling for ultrasonic wire splicing (normally above 200,000 welds)

Advantages of Ultrasonic Metal Welding

- Low-temperature process does not affect material properties

- Pure metallurgical bond for many non-ferrous materials

- Ability to weld dissimilar materials

- No consumable materials such as splice clips or solder

- Environmentally friendly process

- Consistent weld quality, mechanical, and electrical properties

- Fast cycle time

- HMI friendly

- Operator safety with no fumes or chemicals such as lead

The Process

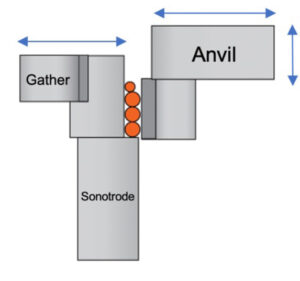

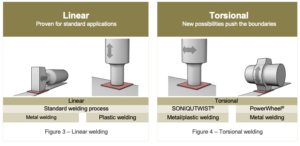

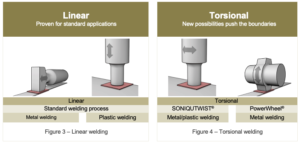

There are two types of ultrasonic welding methods for metal and plastic. Linear welding is the more common technique used by equipment manufacturers and a standard for the splicing of wires (Figure 3). Torsional welding, developed by Telsonic, came into the picture over a decade ago. The torsional welding technique can be used for most common applications of linear welding. However, because of its unique capabilities, it has certain advantages in terms of the application’s geometrical shape and its gentle process that leads to a wider spectrum of applications in the market. In fact, this technology is sometimes found to be the only solution for electric car battery manufacturers and in the termination of high-voltage cables (Figure 4). Other examples where torsional ultrasonic welding proves to be the superior method are bus bars, 3D terminals, and integrated gate bipolar transistors (IGBT).

Ultrasonic Welding Techniques

Current examples of EV Applications for Ultrasonic Welding

Figure 5 – Examples of ultrasonic welding applications for automotive

How it Works:

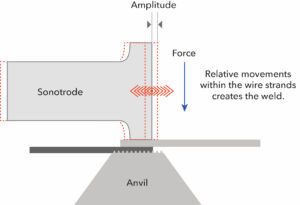

The wires are stacked between the vibrating/oscillating tool (sonotrode) and the anvil block. They are confined in a pre-determined space before the static force is applied through the anvil. As oscillation ensues, the metal surfaces heat up and plasticize, and the strands are bonded together by inter-mingling at the molecular level (Figure 6). The result is a continuous weld with a finely-grained structure like the structure of cold-worked metals. The entire process is very rapid, with welds typically completed in a fraction of a second. Most common splicing machines used today are operated at 20KHz frequency mechanical vibration. The vibration under the force dissipates any contaminants and starts the cold friction welding until the splice is completed. The temperature rise of the welded material is less than 30% due to the friction force at the welding interface. Therefore, there is no hardening of the wire material which makes the wire strands brittle in the weld transition area. This is one of the many advantages over resistance welding, which involves melting of the material to make the splice nugget.

Figure 6 – The vibration and motion involving ultrasonic linear welding of metal

Basic Welding Parameters and Variables

Wire welding with ultrasonics has also proved to be high-quality and safe in practice. Because the welding parameters can be adjusted and monitored for each application, it is now possible in Industry 4.0 environments.

Welding Parameters:

In addition to the condition of the welding tools and dimensions that are always predetermined, four welding parameters need to be set up. These parameters are normally established by a default given by the machine controller to begin the qualification of the weld quality.

- Width of the weld: Set up by the machine

- Weld energy: The fixed number of watt-seconds to be delivered to complete the weld

- Amplitude: The oscillation that can be adjusted up to 100% capability of the sonotrode

- Force-pressure setting: To set the welding force

Quality Variables:

To control the process for the best quality when welding with fixed energy, the following variables are measured and compared to the upper and lower allowed limits determined by the machine or the user.

- Weld time (duration of welding)

- Compaction height before ultrasonic is started

- Final weld height

- Power consumed

Stable Production and Data Integrity

Ultrasonic metal welding is a crucial process for all aspects of wire harness assemblies due to its ability to provide a reliable bond to meet all low and high current-carrying characteristics. Therefore, certain standards and specifications have been prepared by individual companies. USCAR 45 & 38 for Ultrasonic Wire Splicing and termination are some examples, as well as other specs that can be applied to most industrial products in the market. The following table is a summary of ultrasonic welding quality guidelines.

Table 2 – Ultrasonic Metal Welding Quality Guidelines

In today’s fast-paced development of electric vehicle batteries and high-voltage connection systems, prompt response with a solid joining solution is necessary. Product engineers must select the joining technique while they are in the design and development stage. This will require communication between welding solutions providers and product designers to speed up the process and have all tooling prepared for prototyping and initial product testing.

As the knowledge of ultrasonic welding grows, more applications are being designed to work with its current capabilities. However, if you are new to the technology, then hopefully this article helps you to better understand some of the fundamental principles of welding technologies and clarifies the potential financial opportunities available in automotive and other industries. There are many factors to consider when choosing the most appropriate joining method before your design is finalized. The information in this article should provide a good start.